Dans le monde du design packaging, les finitions des bouteilles en verre sont plus qu'une simple esthétique; ils ont un impact significatif sur la perception des consommateurs, fonctionnalité, et stratégie de marque. Des finitions soigneusement sélectionnées peuvent améliorer l’attrait visuel d’un article, le faisant se démarquer sur les étagères du commerce de détail et attirer des acheteurs potentiels. Cet article présente les différents types de finitions et leur impact, permettre à votre marque de créer une impression mémorable en alignant les bonnes finitions sur les valeurs de la marque et les attentes des consommateurs.

Comprendre les finitions des bouteilles en verre

1. Quelle est la finition de la bouteille en verre

Les finitions des bouteilles en verre sont des traitements de surface appliqués aux récipients en verre qui affectent leur apparence et leur fonctionnalité.. Ces finitions améliorent l'attrait visuel, contribuer à la reconnaissance de la marque, et améliorer la convivialité du package. En choisissant la bonne finition, les marques peuvent établir une présence unique sur le marché, répondre aux préférences spécifiques des consommateurs, et améliorer l'expérience utilisateur globale.

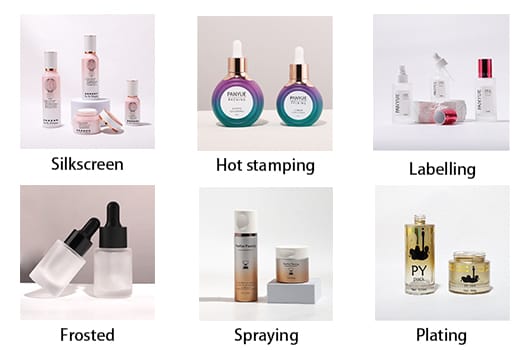

2. Types de finition courants

Finitions givrées

Les finitions givrées créent un doux, aspect élégant grâce aux surfaces en verre sablée ou dépolie à l'acide. La subtile translucidité d'une bouteille givrée ajoute également un sentiment de mystère et rend le produit plus attrayant..

Finition polie

Une finition polie est le résultat d'un polissage minutieux qui donne au flacon un effet brillant. On le trouve couramment dans les produits de luxe, tels que les spiritueux et les parfums haut de gamme, car il reflète magnifiquement la lumière et améliore l'attrait du produit.

Finition texturée

Les finitions texturées ajoutent une adhérence et une expérience tactile, et ceux-ci vont des motifs en relief aux designs complexes qui améliorent la manipulation du produit et le rendent mémorable..

Finitions galvanisées

Une couche métallique est ajoutée à la bouteille pour ajouter un aspect luxueux et une couche protectrice. Couramment utilisé pour les produits haut de gamme dans les industries des cosmétiques et des spiritueux.

En comprenant ces types courants de finitions de bouteilles en verre, les marques peuvent prendre des décisions éclairées qui correspondent à leurs stratégies marketing et aux attentes des consommateurs. Pour plus de finitions de bouteilles en verre, visitez les traitements d'emballage personnalisés de Panyue.

Considérations clés pour la sélection des finitions

Type de produit et application

Produits de beauté: Les produits tels que les parfums et les produits de soins de la peau bénéficient souvent d'une finition givrée ou polie.. Les finitions givrées évoquent le luxe et la sophistication, attrayant pour les consommateurs à la recherche de produits de beauté haut de gamme. Finitions polies, d'autre part, rehausser l’attrait visuel des cosmétiques haut de gamme, réfléchissant la lumière et le dynamisme des couleurs.

Boissons: Pour l'emballage de boissons, les finitions brillantes sont souvent utilisées pour faire ressortir les couleurs et attirer l'attention sur les étagères des magasins.. Un arrière-goût brillant transmet de la fraîcheur et séduit un large public, en particulier sur les marchés très compétitifs des boissons gazeuses et de la bière artisanale.

Fonctionnalité et durabilité

Résistance aux rayures: Certaines finitions, comme brillant ou texturé, peut offrir une plus grande résistance aux rayures, ce qui les rend idéaux pour les produits fréquemment manipulés. Les consommateurs veulent que leurs produits soient impeccables, et les finitions durables peuvent conserver cet attrait au fil du temps.

Maniabilité et convivialité: Des finitions qui améliorent l'adhérence, comme les surfaces texturées, peut améliorer l’expérience utilisateur, spécialement pour les produits utilisés dans des conditions humides ou glissantes. Ceci est particulièrement pertinent pour les flacons cosmétiques pouvant être utilisés dans la salle de bain ou la cuisine..

Avantages de chaque type de finition

Traitement de surface | Avantages |

| Gaufrage | – L'attrait tactile améliore l'interaction avec le consommateur. – Des designs uniques différencient la marque. – Durable et résistant à l'usure. |

| Glaçage par pulvérisation | – Doux, esthétique élégante adaptée aux produits haut de gamme. – La diffusion de la lumière améliore l'attrait des couleurs. – Permet la créativité, conceptions sélectives. |

| 3D Impression | – Permet des conceptions complexes et complexes. – Facilite le prototypage rapide pour un développement plus rapide. – Prend en charge les options de produits personnalisées. |

| Électroplaste | – Fournit une finition métallique haut de gamme. – Améliore la durabilité et la résistance à la corrosion. – Application polyvalente pour diverses conceptions. |

Choisir la bonne finition de bouteille en verre est un aspect essentiel de la conception d’un emballage cosmétique, avec une variété de finitions (givré, en relief, plaqué, etc.) qui produisent différents effets visuels pour créer des emballages qui se démarquent en rayon et trouvent un écho auprès des consommateurs.

Pendant que vous explorez vos options d’emballage, envisagez de consulter Panyuepack, un leader du packaging cosmétique avec 18 années d'expérience qui comprend les subtilités des finitions des bouteilles en verre et l'importance de fournir un produit de haute qualité à vos clients.

Nous pouvons proposer des finitions avec des effets différents selon votre marque, garantir que vos produits se démarquent sur le marché concurrentiel. N'hésitez pas à contacter l'équipe de professionnels qui pourront vous aider à explorer les possibilités passionnantes des finitions de bouteilles en verre pour vos produits..